1. Independent design and mold manufacturing capabilities have reduced the new product development cycle from the previous 40 days to just 20 days.

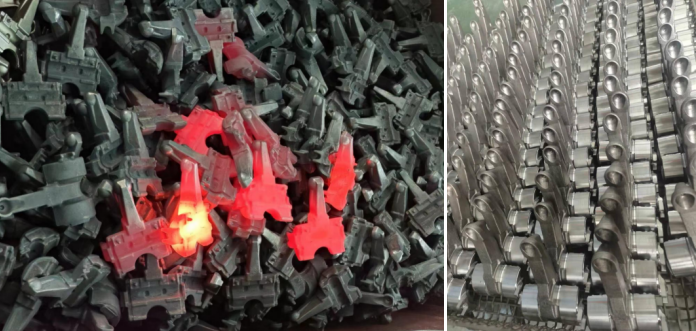

2. In-house forging, heat treatment, and cold extrusion production lines enable self-sufficiency, accelerating delivery cycles and reducing safety stock.

3. Breakthroughs in precision forging technology enhance product quality, optimize processes, reduce costs, and improve efficiency.

4. Monthly production capacity: 50,000 sets

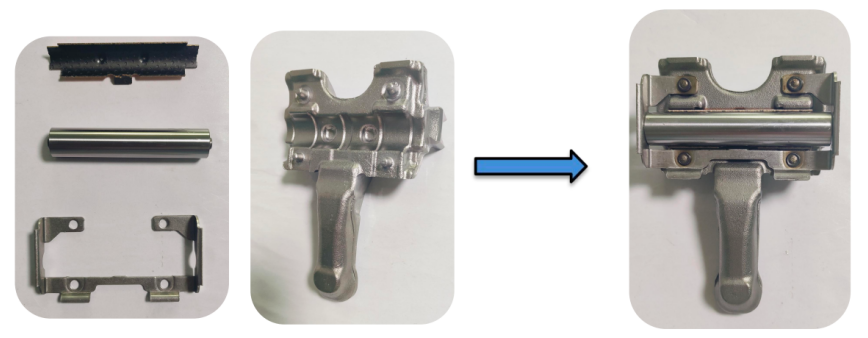

1. Material: 16MnCr5 or 20CrMnTIH

2. Heat Treatment Process: Carburizing

3. Key Control Points: R9 inner circle, R27.5 outer circle, fork, R8.5 ball socket, hot riveting assembly

4. Data Affected by the Lever in ADB:

Lever ratio

Brake clearance

5. Common Issues with the Lever:

Cage fracture

Wear-resistant layer of the bushing prone to peeling

Fork fracture

6. The cage is made of Baosteel HC750 material to enhance strength and prevent fracture.

7. The lever has undergone customer testing, including bench tests, inertia tests, high and low-temperature tests, vibration tests, and torsional fatigue tests (1.0 MPa air pressure) for 600,000 cycles without damage.

Adjusting Mechanism Assembly

Caliper Adjuster Mechanism